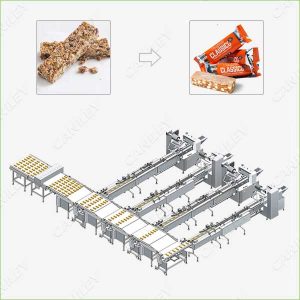

Cereal bar is a very popular meal replacement because of its ready-to-eat and portability. With the increase in demand, cereal bar manufacturers have higher and higher requirements for the speed of production and packaging. However, while increasing the speed, it is necessary to pay more attention to the quality of the cereal bar packaging, which requires manufacturers to comprehensively consider technology and quality when choosing a cereal bar packaging machine.

Why Use the Cereal Bar Packaging Machine Instead of Manual?

- Can greatly improve labor productivity. Reduce labor intensity and improve labor conditions.

- Guaranteed packaging quality. According to the requirements of cereal bar packaging, machine packaging can obtain packaging finished products with consistent specifications according to the actual shape and size. Manual packaging is not guaranteed.

- Reduce packaging costs and save storage and transportation costs.

The bar packaging machine for sale is one of the most popular models in our factory. This machine can also be used for other food, such as chocolate, candy, protein bar, etc.

Cereal Bar Packaging Machine Features:

- Intelligent. The system can store more than 100 product parameters. The touch screen displays parameter settings, operation instructions, error signals and quantities, and the operation is simple.

- Long service time. The parts are easy to replace, and the overall structure is simple in design, which is suitable for long-term use.

- low noise. Ensuring the health of the production environment and workers.

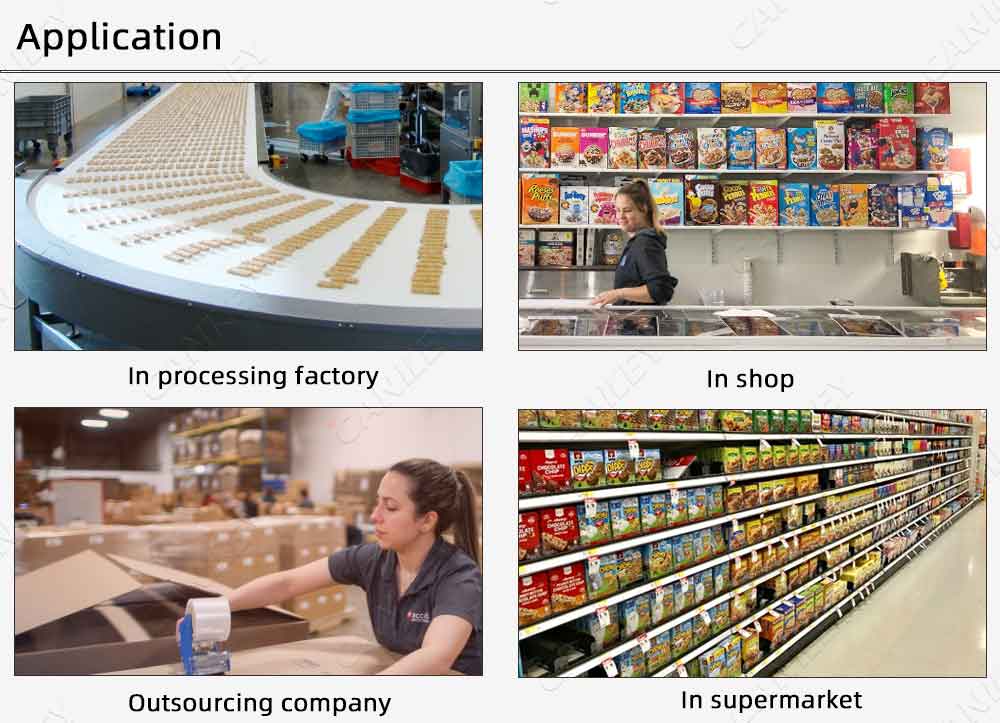

Application:

Packaging Material of Bar Packaging Machine for Sale:

In order to attract more customers, manufacturers will choose a variety of packaging materials. But the essence of these packaging materials are composite packaging films.

Common composite films are PE (polyethylene film), with a thickness between 25 microns and 150 microns. CPP (cast polypropylene film), the thickness can be adjusted at will. The thickness of VMPET (aluminized polyester film) is commonly 12 microns. The thickness of VMCPP (vacuum aluminized cast polypropylene) can be adjusted at will. The thickness of AL (full name of aluminum foil) is generally 7 microns. Some printed films can also be placed in the middle as composite films, such as PET and Nylon-BOPA films.

Reviews

There are no reviews yet.