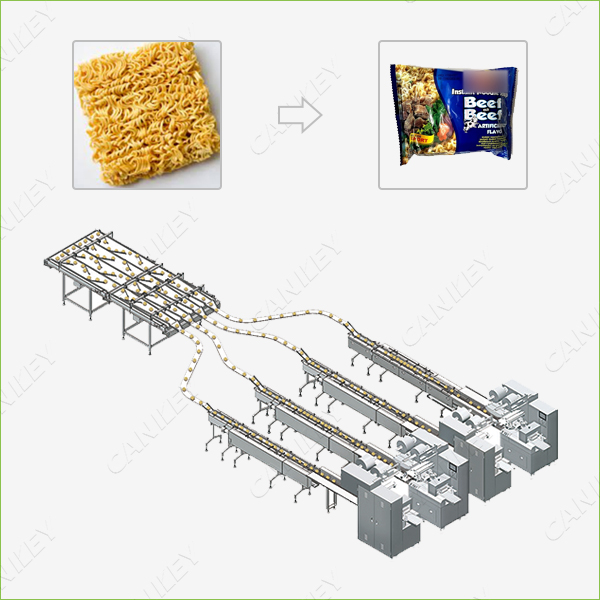

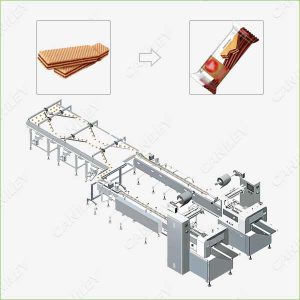

The instant noodle packaging solution includes an instant noodle sorting line, a flow wrap machine, a sauce pouch dispenser machine, a boxing machine, etc. Mainly suitable for round instant noodles, square instant noodles, one or more pieces of automatic high-speed conveying, sorting and packaging.

Advantages of Instant Noodle Packaging Machine:

- Less waste: Adopt multi-stage speed regulation, servo drive control, simple and convenient operation, high control precision, low energy consumption, and the qualified rate of packaging is as high as 99.9%.

- Efficient: The instant noodle packaging machine can be directly connected to the front-end instant noodle production line to meet the requirements of large-scale and mass production packaging.

- Stable operation: It can be individually designed according to the characteristics of instant noodles. In the case of instant noodles congestion, stacking, and unsuccessful steering, it will be automatically removed without stopping to ensure 24-hour continuous production.

- Long life: The electrical appliances are highly formulated, with strong corrosion resistance, and the normal service life of the equipment is 8-10 years. Humanized design, installation, disassembly, maintenance, convenient maintenance, high input-output ratio.

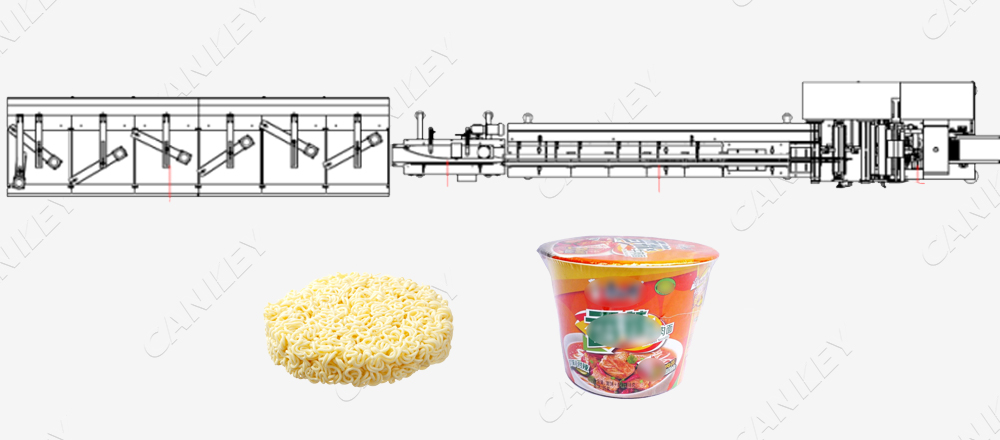

In addition to bags packaging, we also provide packaging solutions for cup instant noodles, which contain put instant noodles into cup- cup sealing- cup shrink wrap.

Why Choose Us?

R & D design, customized on demand

- More than 50 technical research and development teams have obtained a number of national patented technologies.

- Introduce cutting-edge technologies at home and abroad, and make customized equipment according to customers’ packaging materials and usage scenarios.

Quality control, strict testing

- Establish a sound quality control management system to ensure machine quality.

- Perfect raw material inspection, whole manufacturing process inspection, control the quality of packaging equipment from the source and production details.

- Establish a complete quality control management system and process for equipment commissioning and acceptance.

Special personnel, full service

- Pre-sale: Understand the customer’s equipment usage scenarios and usage requirements, check the site on-site, and communicate the preliminary plan.

- On sale: Test the machine according to the samples sent by the customer, shoot the test machine video, and prepare the test machine report to the customer for confirmation.

Reviews

There are no reviews yet.