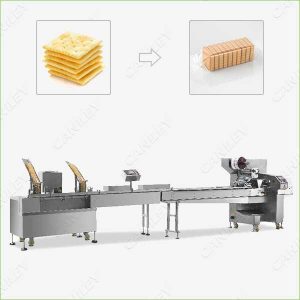

How is bread packaged? Many bread manufacturers choose to use flow wrap machines. So how does it complete the packaging process?

The bread is conveyed horizontally by the conveying mechanism to the inlet of the film(at this point the film has passed through the bag making machine in a cylindrical shape). Then run synchronously, going through the heat sealing and cutting process. Compared to vertical packing, flow wrap machine is suitable for relatively unique items or integrated items such as blocks, bars and balls.

Small Bread Packaging Machine Structure:

- Machine body: Parts used to mount, fix and support all components of the packaging machine and meet mutual movement and position requirements.

- Sorting and supplying systems for packaging materials: A system that cuts or arranges packaging materials into lengths and transports them one by one to a predetermined station.

- Packing execution: The mechanism that directly completes the packaging operation, including the mechanism that completes operations such as packaging, sealing, printing the date, etc.

- Finished product output mechanism: Used to output the finished packaged bread. The output of some packaging machine is completed by the main transport mechanism, or is unloaded by the product’s own weight.

- Power machinery and transmission systems: The power of mechanical work is usually the electric motor of modern packaging machinery.

- Control system: The output of power, the operation of the transmission mechanism, the operation and coordination of the packaging actuator and the output of the packaged product are all controlled by the control system. This mainly includes packaging process control, packaging quality control, failure control and safety control.

Bread Packaging Machine Features:

- High quality, stable and reliable operation, and parts are burn-in tested to ensure longer life of parts.

- The bread packaging machine is highly accurate, with speeds in the range of 40-230 bags/min, and within 0.5mm of error.

- Use a smart temperature controller and precise temperature control to ensure an aesthetically pleasing, smooth seal.

- The blade guard is equipped with protectors to prevent accidents during operation.

- The length of the bag can be set on the computer, so there is no need to change gears or adjust the length of the bag. The touch screen can store the packaging process parameters of various products, and can be used at any time without resetting when changing products.

Tips:

Before and after the flow wrap machine is turned on, the inside and outside of the machine should be cleaned, and the areas where bread passes through should be cleaned. Before starting the machine, the oil cup on the horizontal seal bracket should be filled with 20# oil every day before starting the machine. Unused packaging film should be removed after working to prevent bending of the support tube.

Reviews

There are no reviews yet.