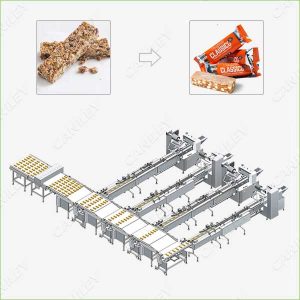

Horizontal packing machine is widely used packaging equipment, with high speed and good packaging effect, which is deeply loved by food production enterprises.

At present, the horizontal packing machine is developing very well in the packaging machine industry. It not only has advanced packaging technology, but also has well-made equipment and powerful functions. Because the packing machine not only adopts the intelligent man-machine control interface, but also adopts the dual-frequency inverter main control, the sealing and cutting technology of high-sensitivity photoelectric eye color mark tracking, and also has many advanced functions and skills.

Hard Candy Packaging Machine Structure:

- PLC: PLC intelligent control system, more stable operation, can adjust parameters without stopping.

- Schneider inverter: Three-phase multi-stage speed control, the bag length can be set and cut immediately, saving time and film.

- High-sensitivity cursor electric eye: The high-sensitivity cursor electric eye is used to accurately track the roll film color block, which effectively prevents the phenomenon of deviation during the film feeding process.

- Ink roller tracking coding machine: Track and print production date, batch number, etc., high printing speed, wide printing area, flexible printing and typography.

- End seal cutting area: Rotate the constant temperature heat sealing cutter to seal the front and rear ends of the packaged product to avoid curling or holes in the sealing position.

- Stainless steel conveyor panel: Fast and accurate material handling, the fastest conveying speed can reach 230 packs/min.

- Linkage film shaft: The multi-linked film reel is used to coordinate the film pulling process, adapt to more film materials, and feed the film more smoothly.

Hard Candy Packaging Machine Features:

- Energy saving and power saving, high efficiency, function adjustment and skill improvement can be carried out according to different market needs. Because it is mastered by the software as a whole, it can maintain its own advantages and keep pace with the times.

- The transmission system is simple and stable, which can not only complete feeding, packaging, sealing and cutting in one step, effectively improve the packaging efficiency.

- The scrapping rate is low, and the transmission system is equipped with active detection and installation, which will not let the empty packaging enter the sealing and cutting process, and will automatically stop and sort, which can not only improve the quality but also prevent the packaging film from being damaged.

- A variety of product parameters and formulas can be stored, and they can be downloaded and used without repeated settings.

- The structural layout conforms to ergonomic mechanics, which can facilitate and quickly carry out hygienic cleaning, maintenance, maintenance and overhaul of the machine.

The hard candy packaging machine can be equipped with an automatic feeding system to improve the overall packaging speed.

Reviews

There are no reviews yet.