Fully automatic horizontal flow packing machine has a wide range of applications in the food processing industry, it can pack granola bar independently. It can increase the aesthetics of the granola bar and prolong the shelf life of the granola bar. The granola bar packaging machine is suitable for packaging all kinds of solid products. After the granola bar are packaged, they will form a group, which is convenient for transportation and storage and can also increase their selling prices in the market.

Horizontal Flow Packing Machine Structural Features:

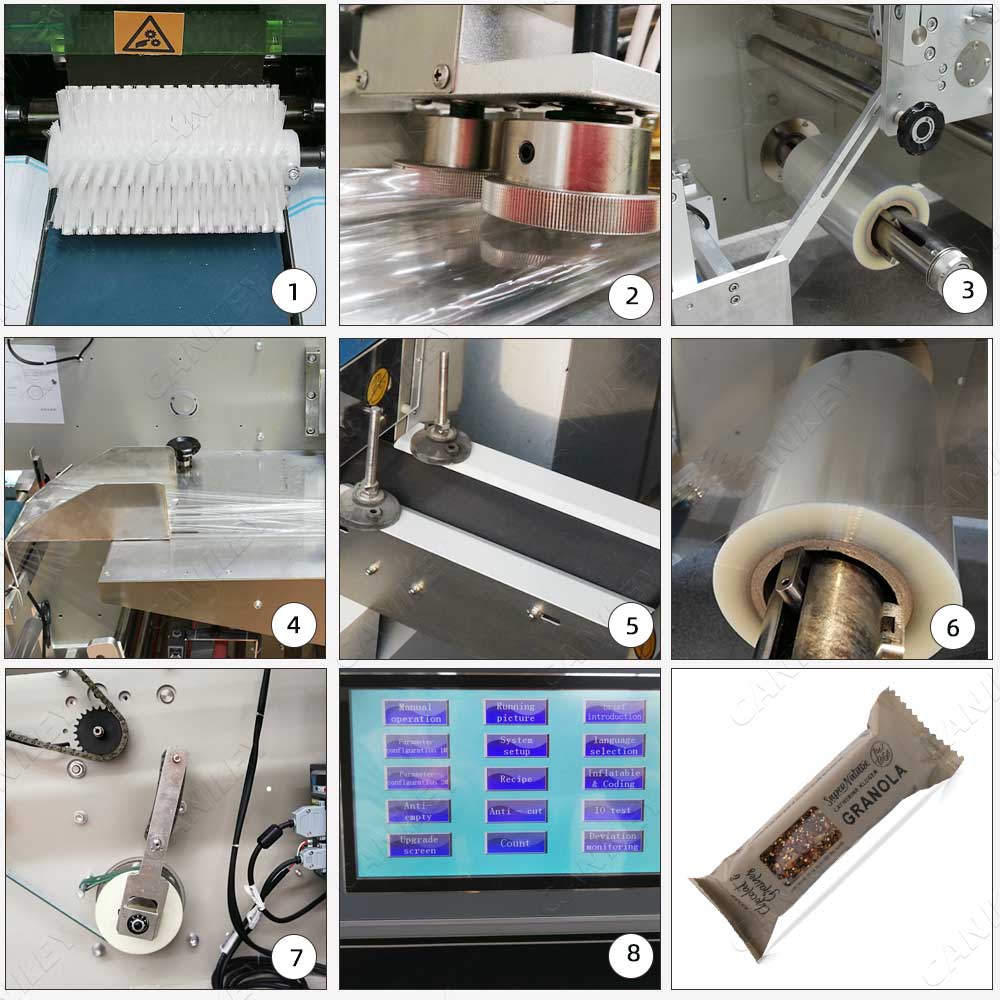

- Finished conveyor belt and press brush: Due to the fast packaging speed, the bags may fly out during the conveying process, and the pressing brush keeps the product on the conveyor belt.

- Heating wheel vertical seal: Compared with the ordinary heating block, the heating wheel heats more uniformly, heats and seals at the same time, and greatly improves the sealing performance of the bag.

- More precise film roll conveying structure: Make the packaging film run stably during the rolling film forming process and the working process of the encoder.

- Bag making mechanism: The metal plate forms the film into a bag shape.

- Finished conveyor belt: Can be connected with other packaging equipment, belt length can be customized.

- Film roller: The maximum width of the packaging film is 500mm, and the packaging range is large.

- System: Servo motor drive, high precision.

- Operation interface: Computer control, no waste of packaging film.

Granola Bar Packaging Machine Characteristic:

- With dual frequency conversion controller, the bag length can be set and cut at any time during use, and there is no need to adjust the idling. It can save packaging raw materials and realize one-step delivery. It saves time and materials.

- With textual man-machine interface parameter setting, you can operate the machine proficiently according to the operation instructions.

- Stable performance, good compactness and beautiful appearance.

Precautions for Using:

- Enterprises should regularly check, clean and lubricate each machine for maintenance. Also do a good job of heat dissipation and ventilation. Do not place the granola bar packaging machine in a high temperature, humid and dirty environment, not only to prevent product contamination, but also to prevent equipment performance from being affected.

- The inspection and maintenance of the machine must be carried out by professional electrical maintenance personnel when the power is turned off.

- Before each start-up, check the work surface, input belt, and horizontal sealing knife holder, and there must be no debris.

- In the process of packaging production, because the device that seals and cuts the film is high temperature, do not touch the hot sealing

Reviews

There are no reviews yet.