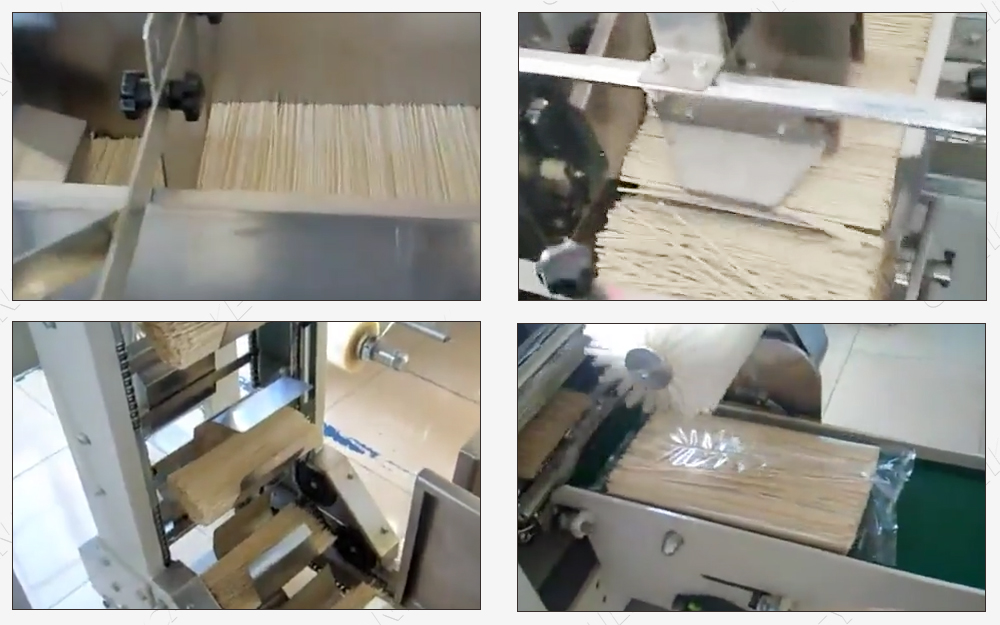

Spaghetti Packaging Machine Composition:

One packaging machine, two weighing machines, two pneumatic online buckets, and two online conveyor lines.

Application:

This pasta packaging machine is used for the packaging of bulk pasta with a length of 180mm to 260mm. The machine completes the whole spaghetti packaging process through the steps of automatic weighing, bundling, lifting, feeding, packaging and forming, sealing and cutting.

Spaghetti Packaging Machine Features:

- The connection is controlled by centralized electrical appliances, intelligently controlling the speed, and the human-computer interaction is more reasonable.

- Each spaghetti packing line only needs 2 to 3 people on duty, and the daily packaging capacity is about 6-8 tons of spaghetti, which is equivalent to the daily output of 10 people.

- Select well-known brand electrical components, host frequency conversion speed regulation, servo motor control sorting, grouping and conveying of packaging film, with anti-cut and anti-air bag functions.

- Use film roll instead of finished bags and save about $100 per day in consumables.

- Accurate weighing, good compatibility, different gram weights can be packaged, with protective devices, high safety.

Use Environment Requirements of Pasta Packaging Machine:

- Site requirements: Indoor use, the ground is flat, no vibration and bumps.

- Ground requirements: For hard non-conductive floors (such as concrete, floor tiles, etc.)

- Ambient temperature: -5~40℃

- Relative humidity: <75%RH.

- Dust: No conductive dust.

- Gas: No flammable and explosive objects and gases, no corrosive gases that seriously damage metals.

- Altitude: ≤1000m

- Grounding Requirements: Independent, safe and reliable grounding environment.

- Grid requirements: There is a stable power grid, and the fluctuation range of the power grid does not exceed ±10%.

Reviews

There are no reviews yet.