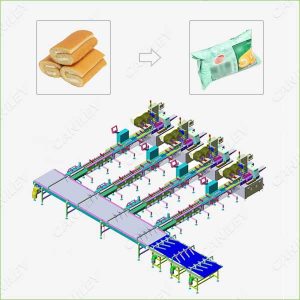

The packaging process of vermicelli noodles requires a professional vermicelli packing machine, usually using pillow type packaging. The application of this machine is very wide. And it can be used for the packaging of different kinds of noodles. Such as dry noodles, fresh noodles, instant noodles, vermicelli, etc.

Noodles and Vermicelli Packing Machine Constitute:

Concise operation area: Using Panasonic PLC intelligent control system to control the operation of the machine, the operation is more stable. The setting parameters can be adjusted without stopping the machine. Human-machine interface display, accurate and convenient control of packaging speed, packaging temperature and other parameters.

Linked film reel: The multi-link film reel is used to coordinate the film pulling process, adapt to more film materials, and the film roll is smoother.

Electronic control components: All electrical control modules are programmed by software, with reliable quality and easy maintenance. Configure Schneider/Panasonic and other electronic controllers.

Custom bag maker: The film enters the bag maker through the film-pulling device, and folds the film through the metal plates on both sides to form a pillow type bag.

Middle sealing area: Heating the double-sided turntable sealing to seal the back of the packaged product. Two sets of middle sealing wheels are used for film drawing, which ensures the precision and stability of the drawing die.

End seal cutting area: Equipped with high-strength and hardness materials to create a rotary constant temperature heat-sealing cutter to seal the front and rear ends of the packaged products.

Noodles and Vermicelli Packing Machine Features:

- A model specially developed for packaging large-size products with a maximum film width of 600mm.

- The thinnest 20μm packaging film can be used for packaging, which greatly reduces the cost.

- Reciprocating sealing, extending the sealing time to ensure a more beautiful sealing effect.

- In order to better realize the stability of the vermicelli packing machine and its own adjustment ability, servo motors are installed in each driving part, and the error accuracy is about 1mm.

- Adopt a new type of heater to provide more stable heat.

- The tension adjustment between the driving roller and the heating roller of the middle sealing part can be performed through the touch screen. It is also possible to change and adjust the product supply position.

Reviews

There are no reviews yet.