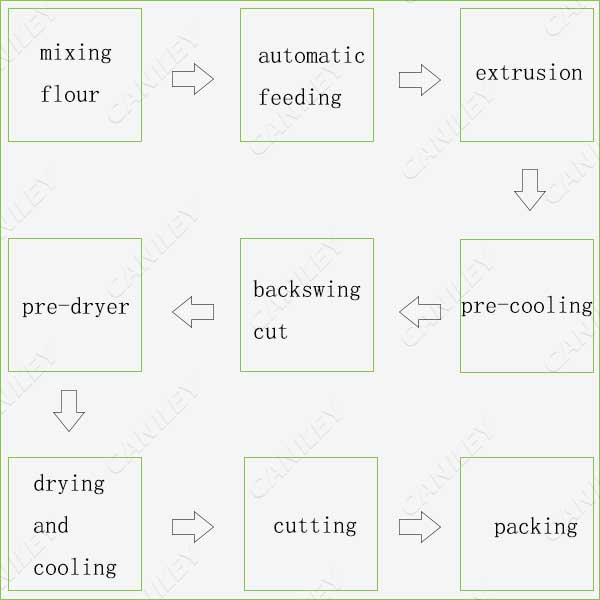

What is the spaghetti manufacturing process? Its main manufacturing process includes:

Step 1: mixing flour

The raw materials are automatically mixed with a certain amount of water and stirred evenly. The amount of water added and the stirring time can be set in advance. The equipment is easy to operate and easy to clean.

Step 2: automatic feeding

Through screw conveying, the dough enters the extrusion process uniformly and stably, and the conveying speed is adjustable.

Step 3: extrusion

The dough is formed by extrusion, and the diameter and shape of the die are adjustable.

Step 4: pre-cooling

The surface of the extruded pasta is cooled quickly by the fan, and it is easy to cut.

Step 5: backswing cut

The spaghetti is automatically hung on the rod and cut, and the length is adjustable.

Step 6: Pre-dryer

The temperature and humidity of the pre-dryer are automatically controlled to save energy consumption.

Step 7: Automatic drying and cooling

In order to achieve a uniform drying effect, the drying tunnel is automatically adjusted according to the drying curve; the dried pasta is cooled to room temperature for packaging, so as to ensure product quality and facilitate storage.

Step 8: Fixed length cut off

Automatically cut the pasta to the required length, the cutting length can be adjusted by PLC, and the incision is neat.

Step 9: packaging

This is the last step in the pasta production process, and a very important one. It can effectively guarantee the storage and transportation of pasta and reduce losses.

According to different packaging methods, our company can provide different packaging equipment. The commonly used spaghetti packaging machine is this weighing type packaging machine.

- According to the customer’s packaging speed requirements, different numbers of weighing units are configured, generally 1-6.

- The control and drive core is composed of single or multiple servo motors, programmable controllers and large color touch-type liquid crystal display screens, which greatly improves the control accuracy, speed regulation range, reliability and intelligence of the whole machine. The bag forming, cutting length, sealing temperature and other parameters are locked more accurately.

- Using dual-drive longitudinal sealing and advanced longitudinal sealing heating technology, the longitudinal sealing temperature is low, ensuring that the probability of scalding the film during operation and shutdown is minimized; and the sealing is good, the texture is smooth and beautiful.

If you have any needs about spaghetti packaging equipment, you can contact us.